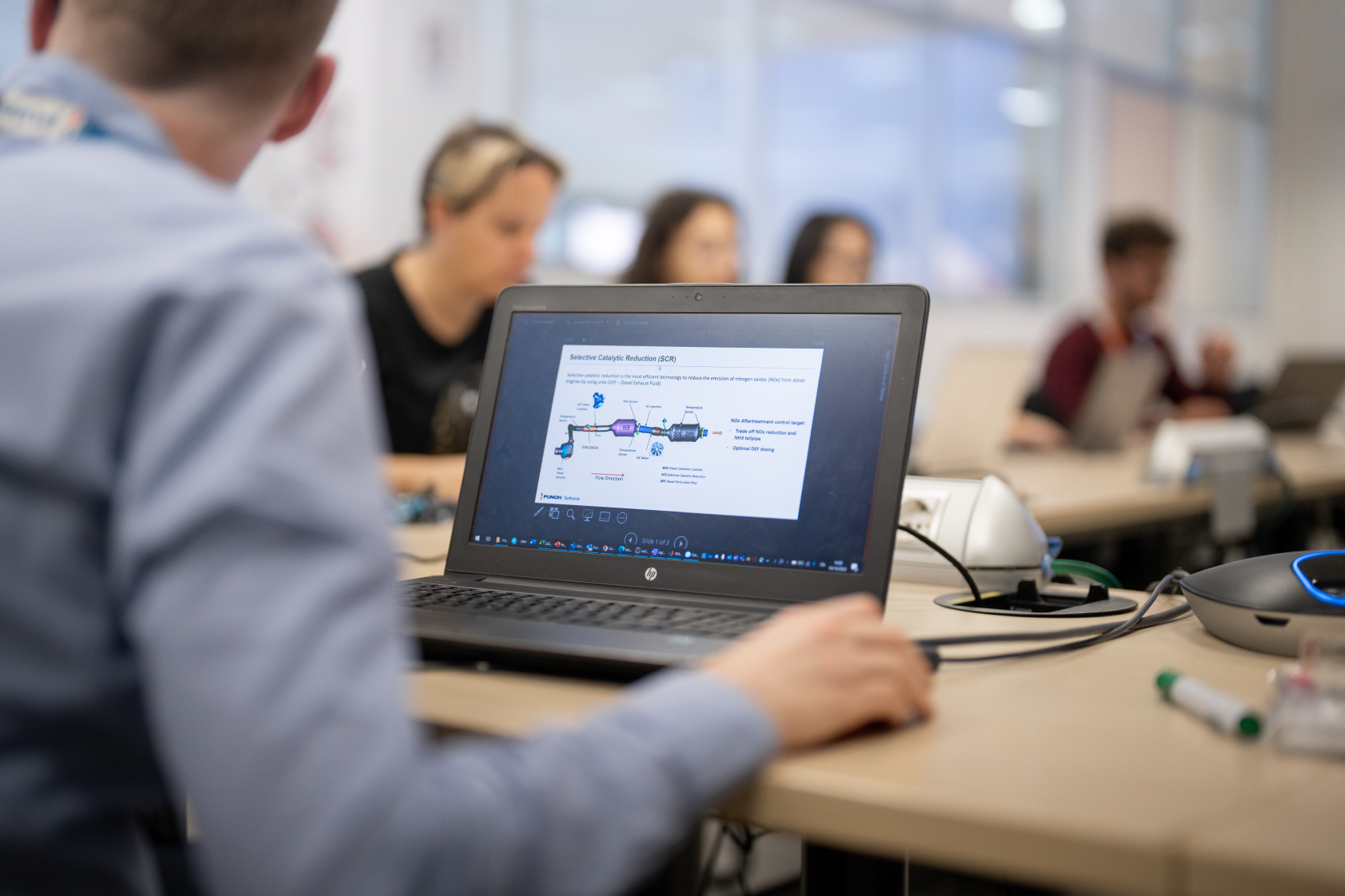

NOx aftertreatment control

Minimizing NOx emissions in modern vehicle systems equipped with Internal Combustion Engines is one of the most important task of their electronic control modules. In the Diesel area the aftertreatment technology reached a relevant degree of complexity to meet the increasingly stringent EU and US emission regulations. Such a degree of complexity on the hardware side led engineers to deeply review and in some cases redesign from scratch the corresponding aftertreatment control functions.

Real Driving Emissions requirements inspired the new design of a Diesel NOx aftertreament control for an OEM customer selling Diesel vehicles on the global market. The new design approach was oriented to the continuous optimization of tail pipe NOx emissions regardless of combustion engine operating conditions. We had to deal with a nonlinear optimal control problem that we solved using a Model Predictive Control approach. The overall control framework that we developed includes non-linear control oriented modelling, Extended Kalman filtering algorithms and Online Optimization numerical solver.

We enabled the customer a flawless emission certification for both EU and US applications, while reducing calibration effort by 15 weeks; this innovative control logic is successfully running on thousands of vehicles contributing to the important task of making Diesel systems compatible with the most stringent emission regulations. (i.e. US ULEV III Bin70 and EU6 plus Real Drive Emissions RDE). This is one example of a successful Dumarey Softronix development and it is a benchmark for the engine controls currently in production in the entire automotive sector.